In-Situ Machining is essential when the part to be machined, either due to its dimensions or due to the complex or expensive operation of its dismantling, cannot be transferred to a workshop. These are the situations where “in-site” machining is essential and its application means significant cost and time savings.

Thanks to the modular design of the BAZUS coordinate tables we can offer any combination of linear axes, paths, and mechanical rigidity necessary to perform any machining on-site

Types of processes

Some examples where “in situ” machining is commonly applied: In many breakdowns in ship or rail engines. In large machines that require to be machined “in situ” in case of repair or maintenance, such as tunnel boring machines, presses… In recovery of wind tower flanges, or of propulsion of the propellers; Machining and grinding on shafts.

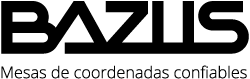

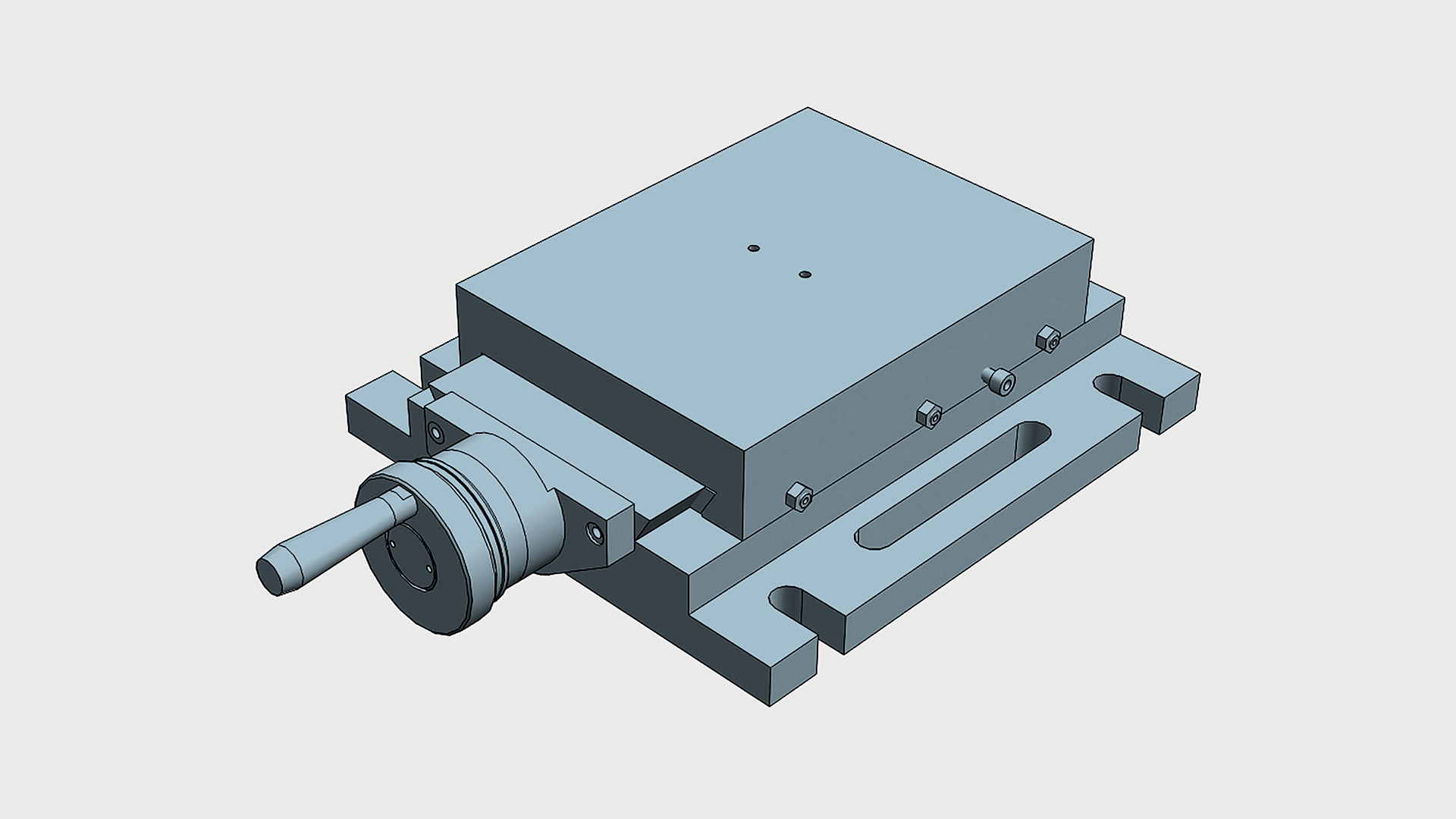

CN Slide unit X for heavy loads

Robust multifunctional coordinate table with a single X axis for application as a linear unit.

Designed for precision work, the CN series of linear units is optimal for positioning, vertical drilling, horizontal drilling, welding, and any other mechanical application where precise position control is required.

The solid and robust design of the linear table allows a large number of jobs to be carried out while maintaining positioning precision and repeatability in any type of linear positioning. An industry standard and outstanding coordinate table that guarantees a long service life.

Show more

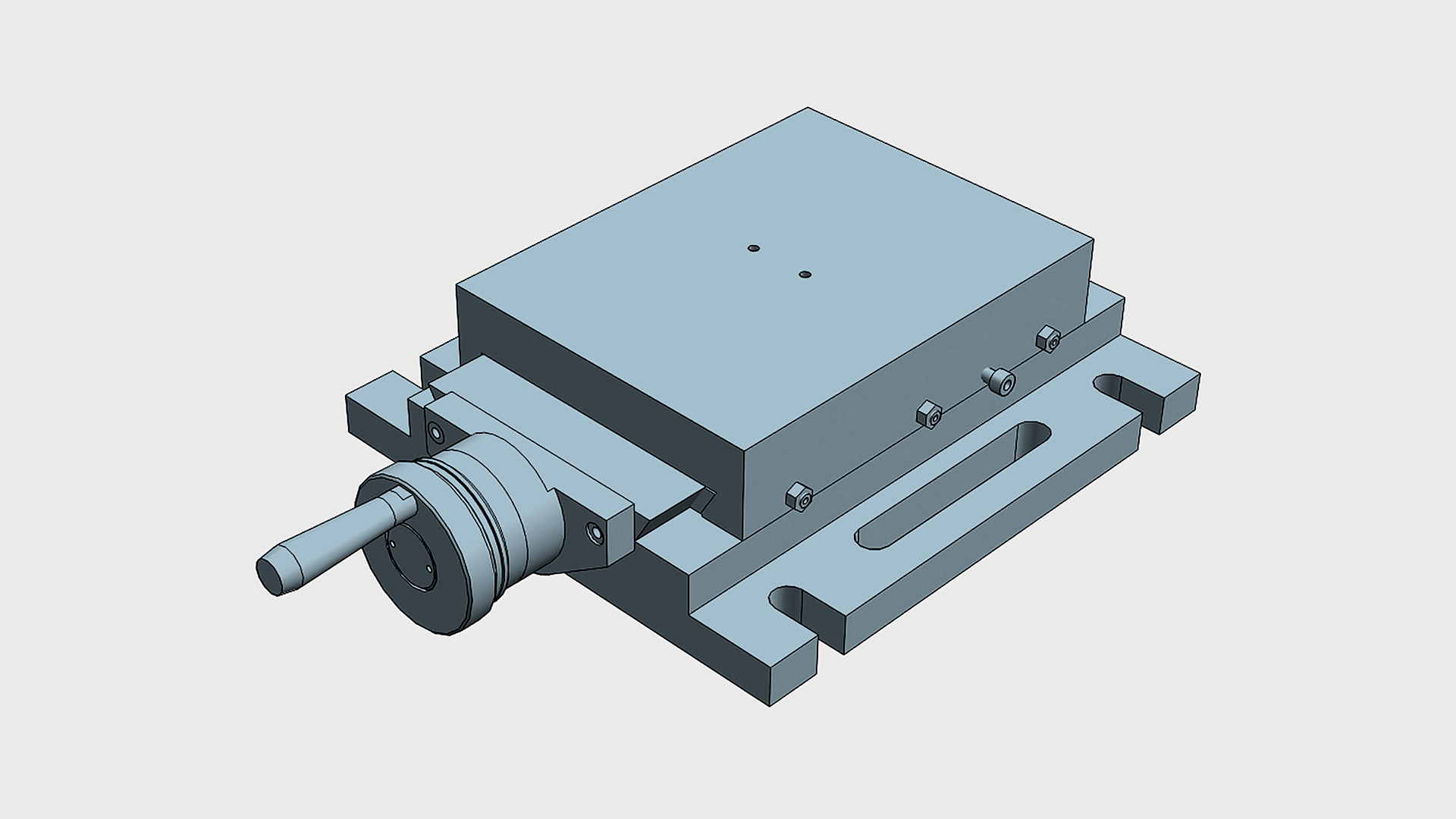

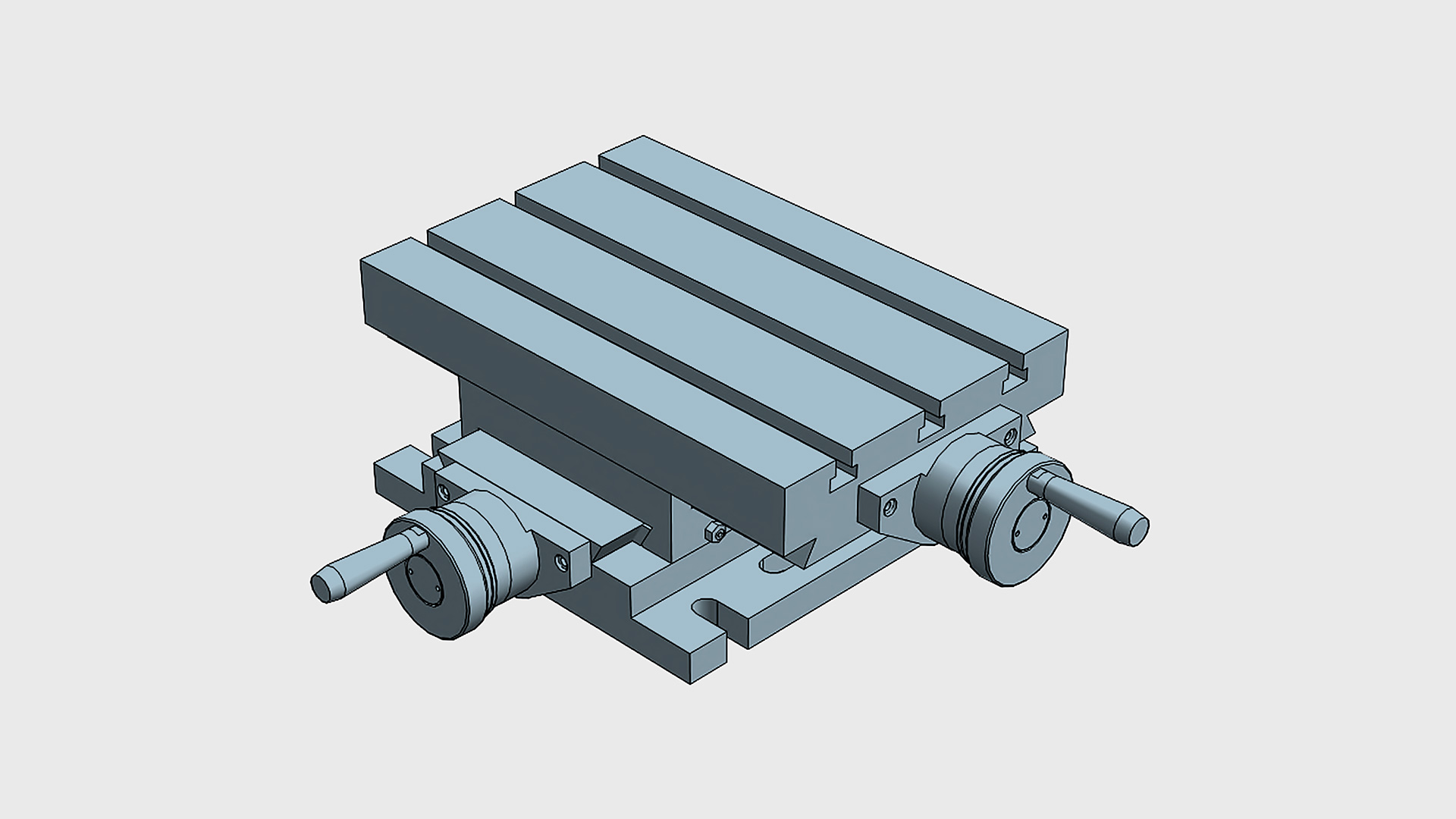

MF Standard XY coordinate table

Two-axis XY multifunctional coordinate table with fixed base for professional use.

Designed for precision work, the MF Series of coordinate tables is optimal for drilling, vertical drilling, horizontal drilling, milling, welding, transfer systems, tool holders and any other mechanical application where precise XY position control is required.

The solid and robust design of the XY Crosstable allows a large number of jobs to be carried out while maintaining positioning accuracy and repeatability in any type of linear positioning. An industry classic that guarantees long life.

All elements of the MF series of manual coordinate tables are made of cast iron (high-quality GG25 stabilized gray cast iron), which gives it extraordinary mechanical rigidity.

Show more

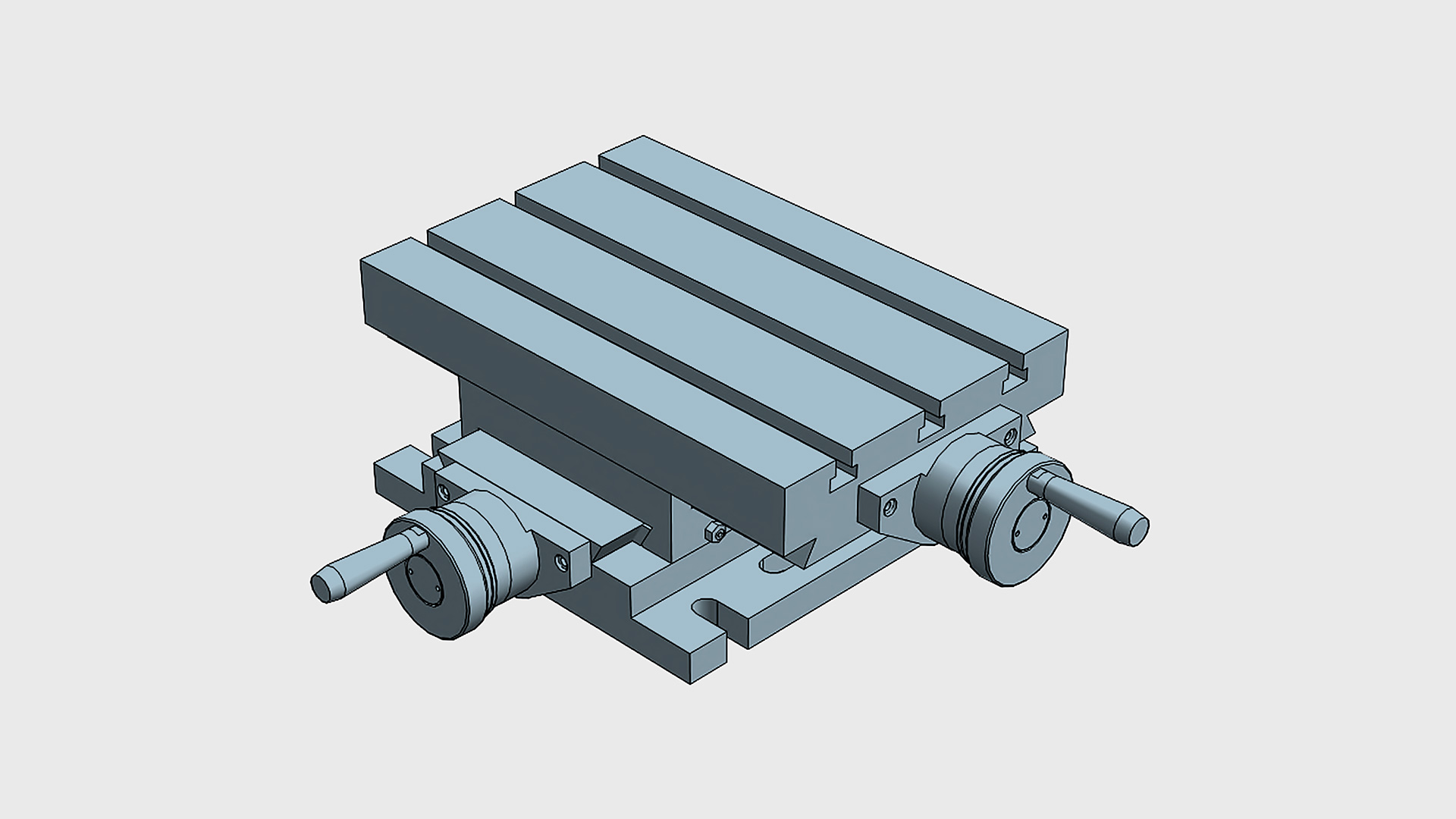

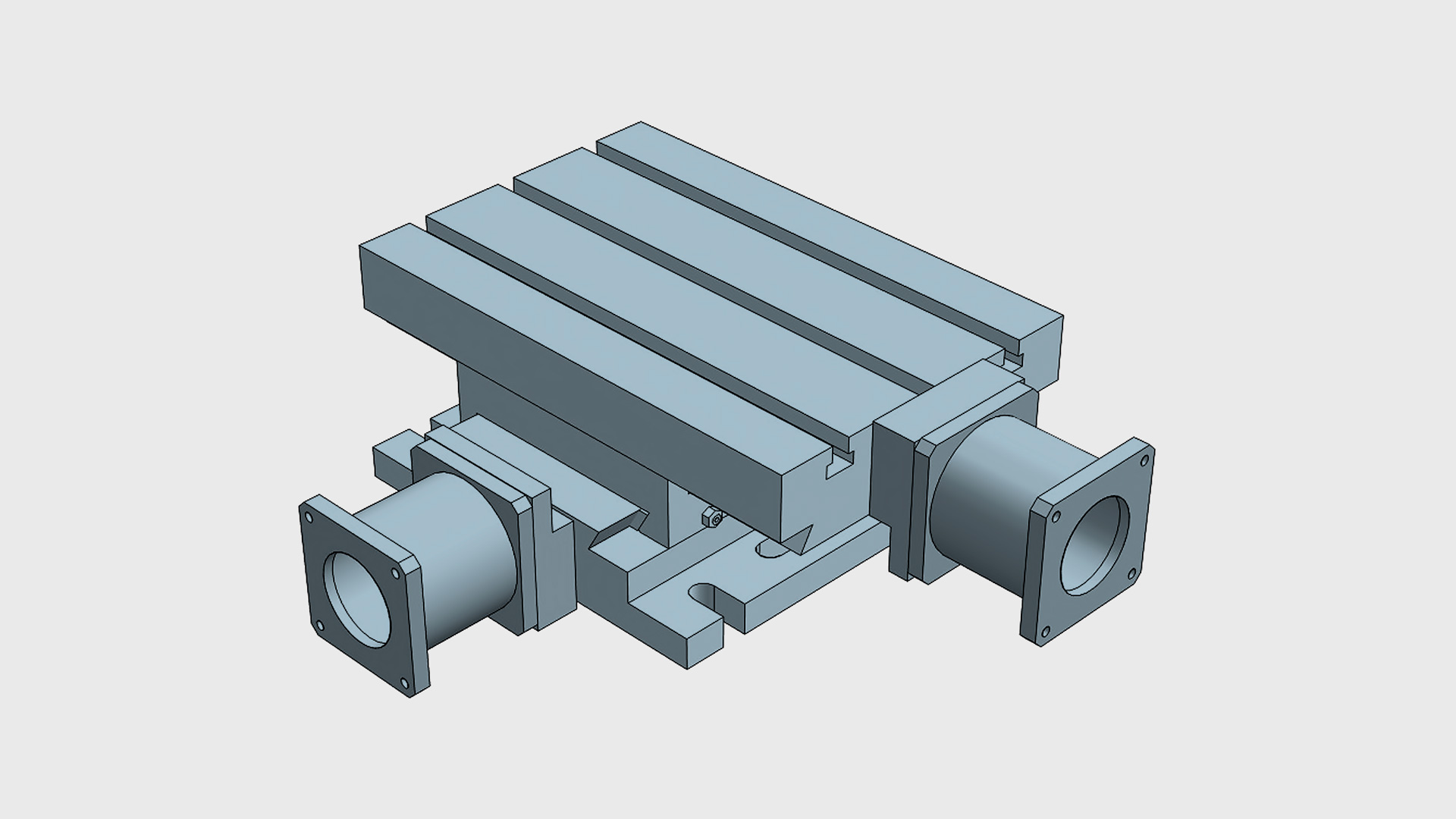

KN Automatic standard XY crosstables

XY automatic two-axis multifunctional coordinate table for professional use.

Designed for high precision automatic work, the KN series are optimal coordinate tables for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of autonomous tool holders and / or heads, as well as in any other mechanical application where automatic control of the XY position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the KN series automatic coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more