The Machine Tool called drill or boring machine is widely used in the industry to process the majority of the holes made in the mechanical parts. These machines stand out for the simplicity of their handling. They have two movements: rotation of the drill by means of transmission by pulleys and gears, and the movement of penetration of the drill into the mechanical part or component, which can be carried out manually, sensitively or automatically, if you incorporate transmission to do it.

Drilling is called the machining operation that aims to produce cylindrical holes in any part, using a drill as a tool. Of all the machining processes, drilling is considered one of the most important processes due to its wide use and easy execution, since it is one of the easiest machining operations to perform and is necessary in most of the components that are manufactured.

The BAZUS coordinate tables allow you to carry out any type of drilling, whether vertical or horizontal, manual or automatic, and also allow the drill’s forward movement to be synchronized with the speed of the drill’s rotation, allowing tapping operations

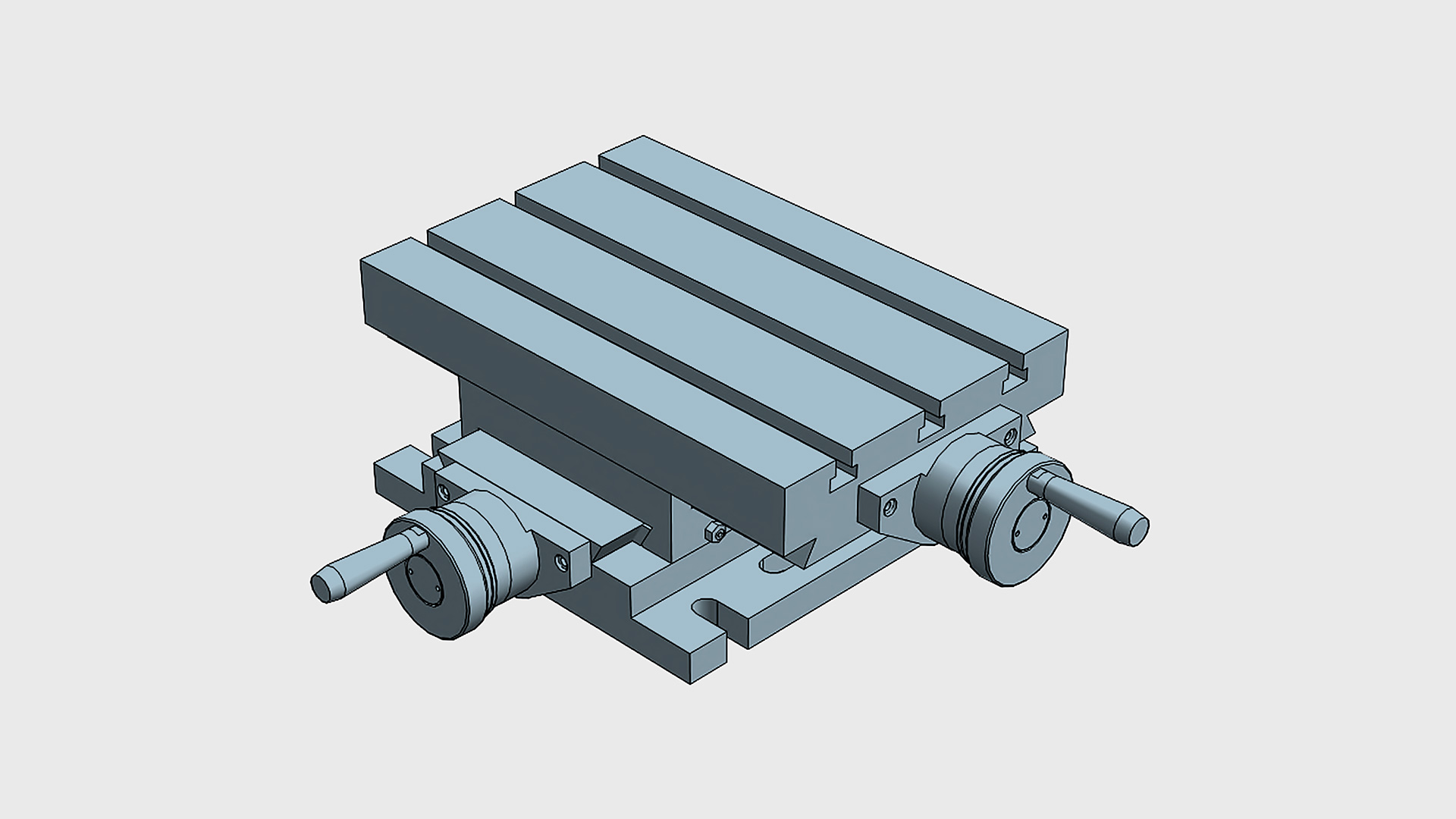

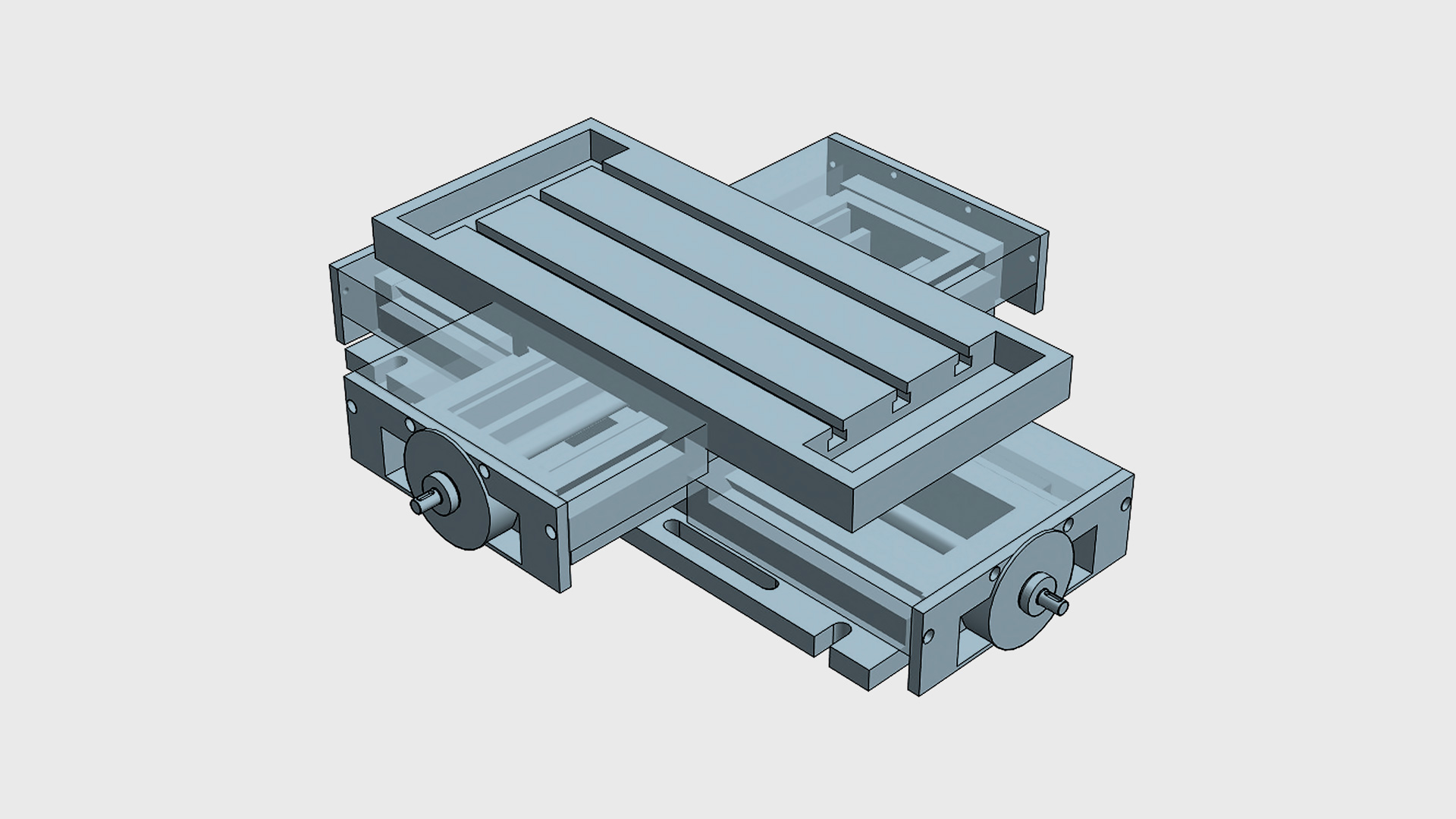

KN Automatic standard XY crosstables

XY automatic two-axis multifunctional coordinate table for professional use.

Designed for high precision automatic work, the KN series are optimal coordinate tables for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of autonomous tool holders and / or heads, as well as in any other mechanical application where automatic control of the XY position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the KN series automatic coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more

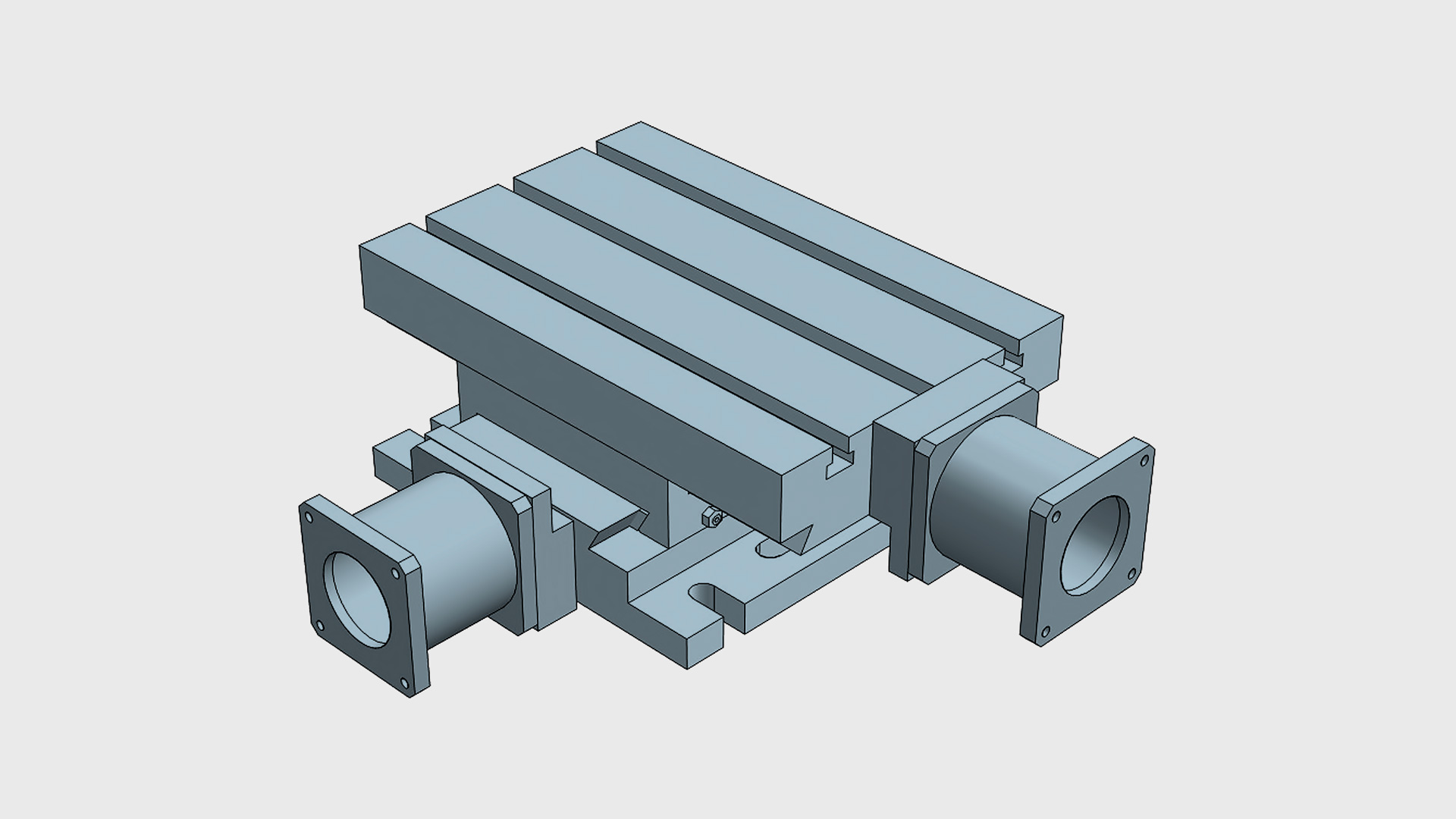

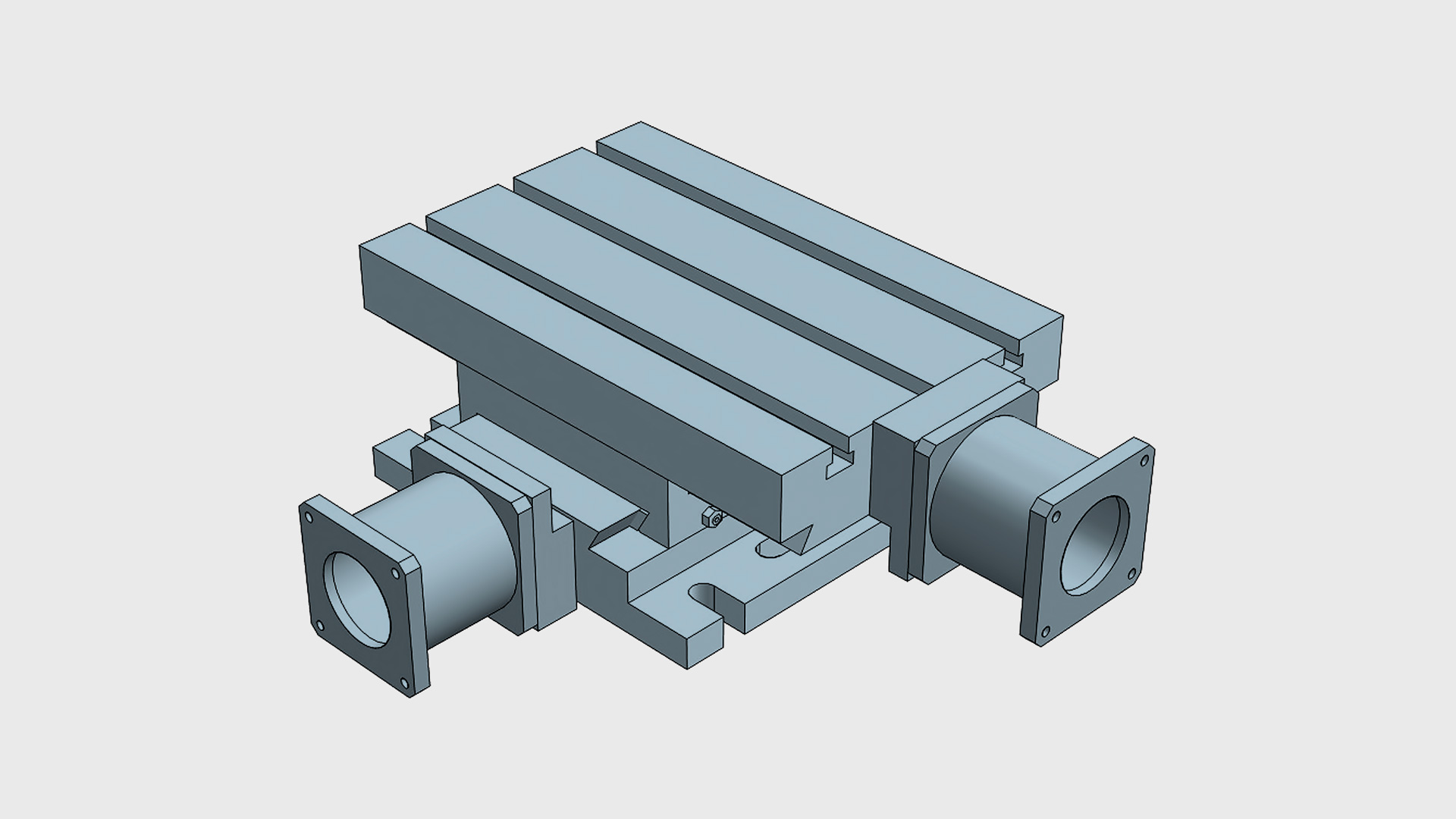

MN Automatic XY crosstables for heavy loads

Coordinate table for heavy loads with two automatic XY axes for professional use

Designed for automatic work with heavy loads, the MN series are optimal coordinate tables for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of autonomous tool holders and / or heads, as well as in any other mechanical application where automatic control of the XY position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the MN series automatic coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more

Kinematik (CNC)

“KINEMATIK SNC”‚ is an automatic positioning system (SNC). It is a simple and, at the same time, an extremely useful solution because it provides the possibility of conducting a large number of activities by programmed movements at specific programmed speeds.

KINEMATIK SNC is controlled by means of the “Quick Panel”, where user find all information to operate with the system in any of its Working Mode (Automatic, Manual and PC Communication). “Quick Panel” is equipped with “Touch screen” to select the Work Mode, buttons Power ON/OFF, Cycle ON /OFF and Emergency Stop.

Show more

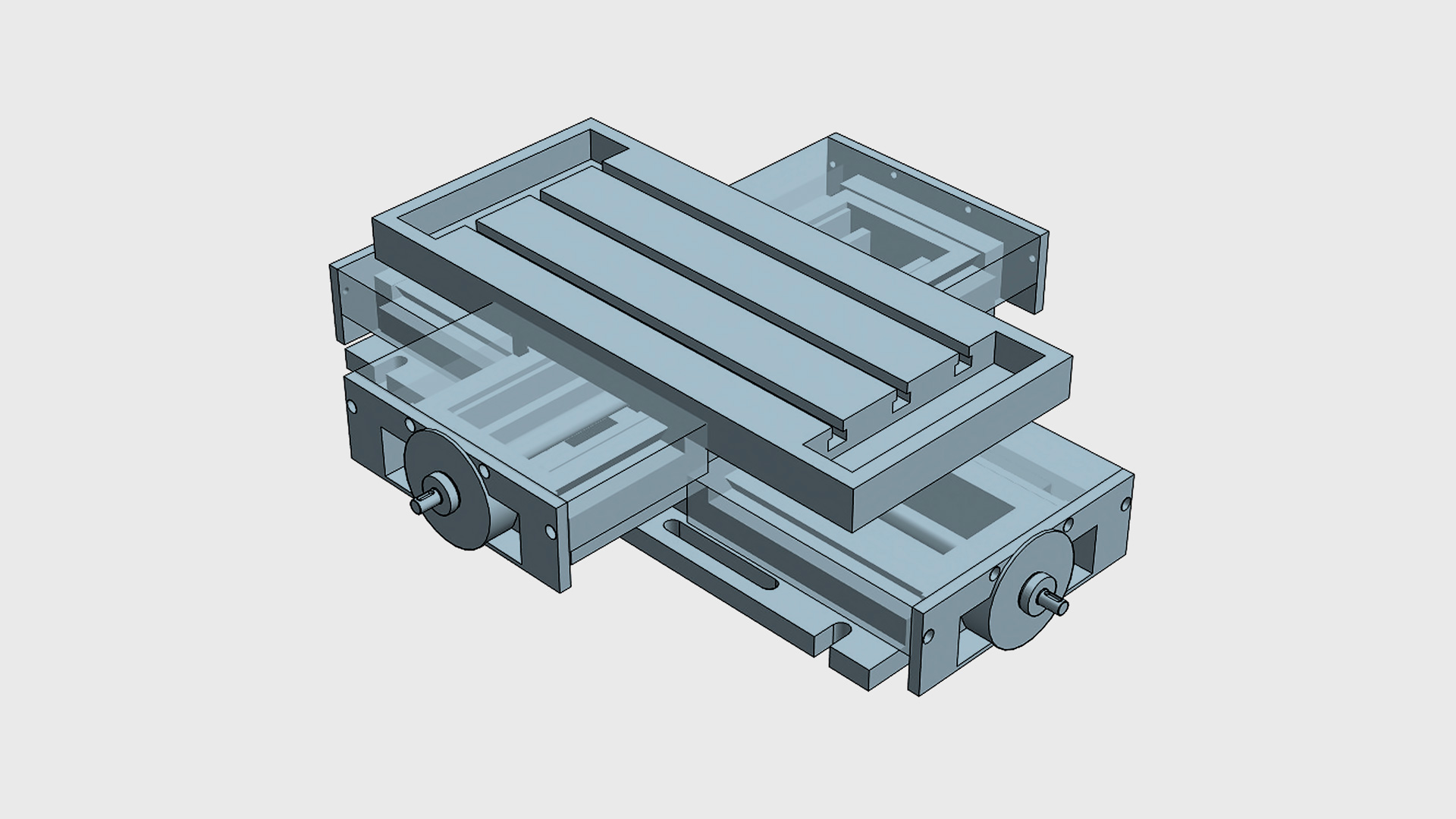

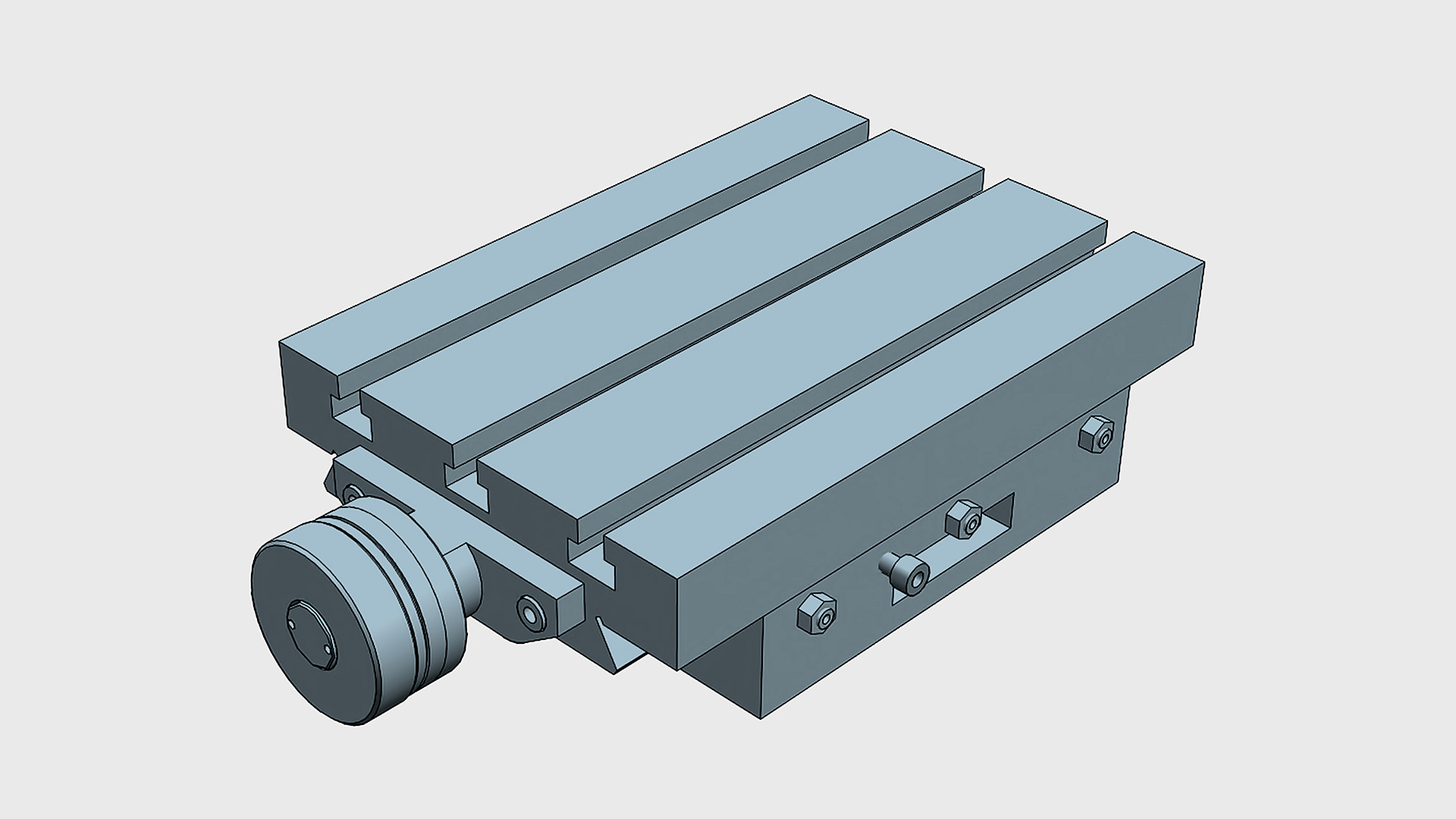

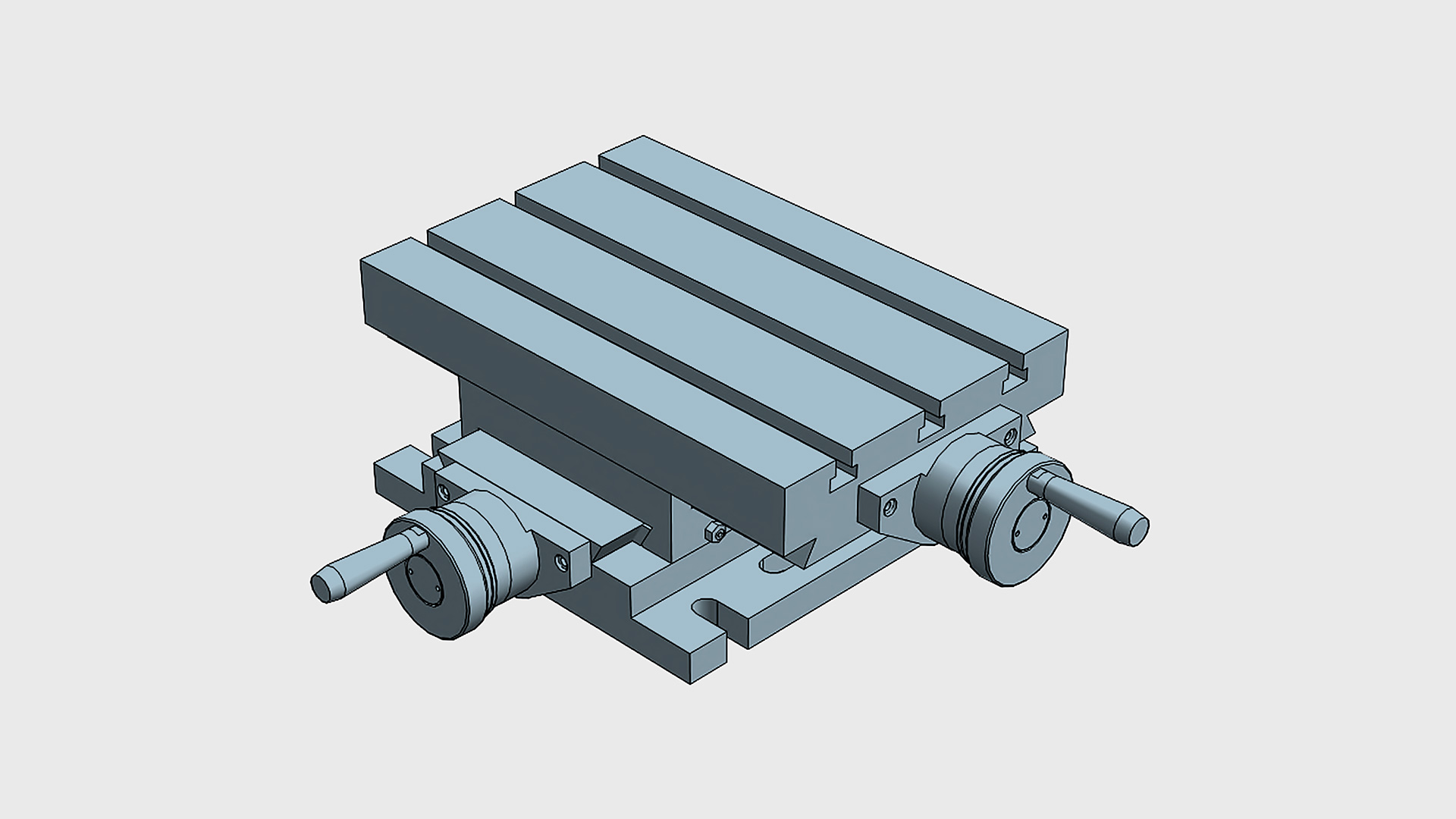

MF DRILL Standard XY coordinate table for Drilling

Fixed basis XY two-axis multifunctional coordinate table for professional use on machines with coolant.

Designed for precision work, the MF DRILL series of coordinate tables is analogous to the MF series, but for works with the use of coolants, drills, etc. The DRILL equipment includes: grooves for refrigerant collection, large diameter handwheel, telescopic protections on the longitudinal axis for the nut and spindle mechanism and, adjustable stop for X travel.

The MF DRILL coordinate table is optimal for drilling applications, vertical drilling, horizontal drilling, milling, welding, transfer systems, tool holders and in any other mechanical application where precise control of the XY position is necessary.

The robust and robust design of the linear table allows a large number of jobs to be carried out while maintaining positioning precision and repeatability in any type of linear positioning. An industry standard and rugged coordinate table that ensures a long service life.

All the elements of the MF DRILL series of manual coordinate tables are made of cast iron alloy (high-quality GG25 stabilized gray cast iron), giving it extraordinary mechanical rigidity.

Show more

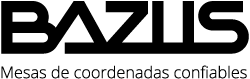

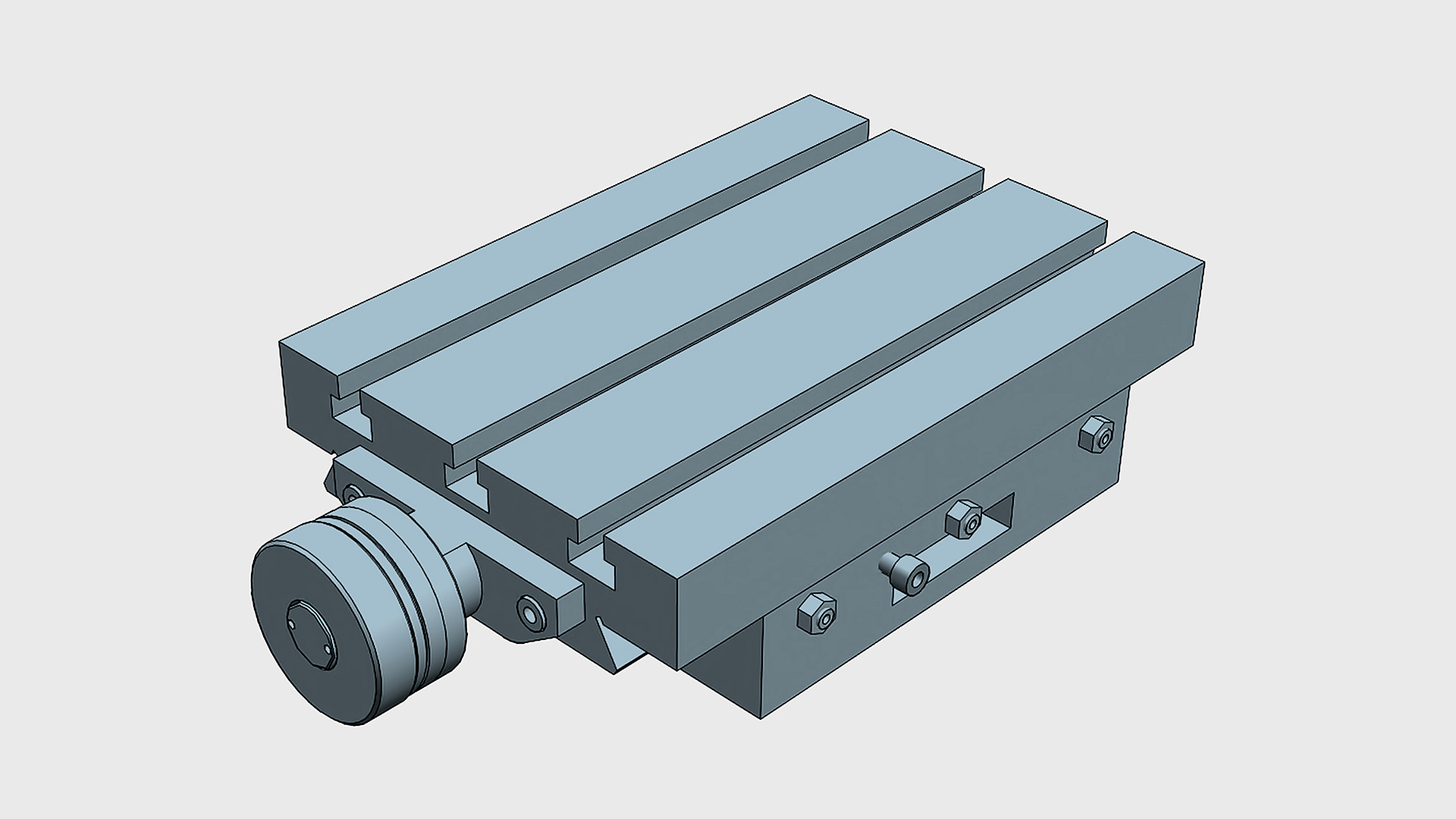

CP Standard X table (horizontal or vertical)

Multifunctional table lightweight with single axis X for linear displacement application.

Designed for precision work, the CP series of linear units is optimal for positioning, vertical drilling, horizontal drilling, welding, and any other mechanical application where precise position control is required.

The solid and robust design of the linear table allows a large number of jobs to be carried out while maintaining positioning precision and repeatability in any type of linear positioning. An industry classic coordinate table that guarantees a long service life.

All elements of the CP Series of manual coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), giving an extraordinary mechanical rigidity.

Show more

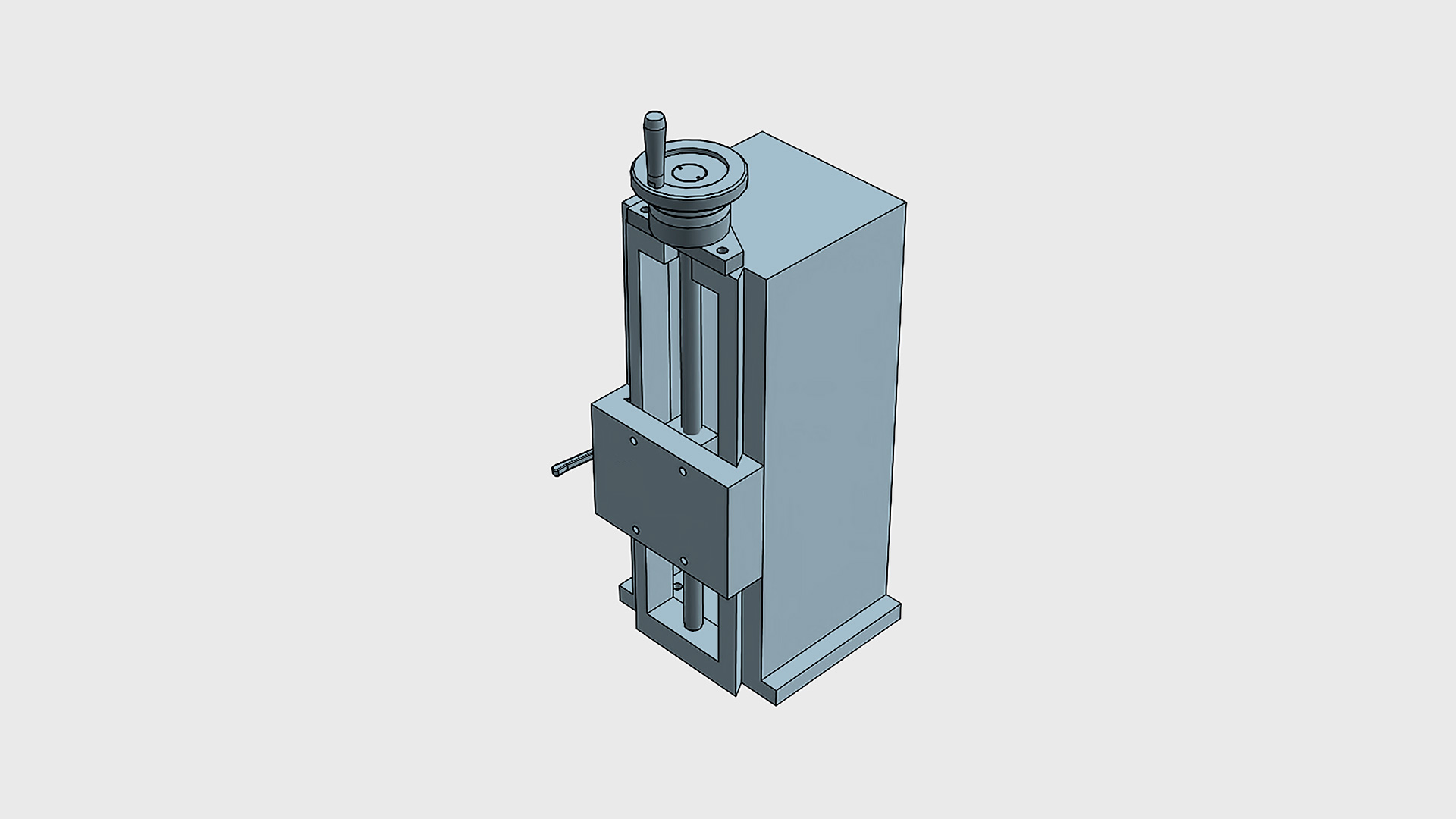

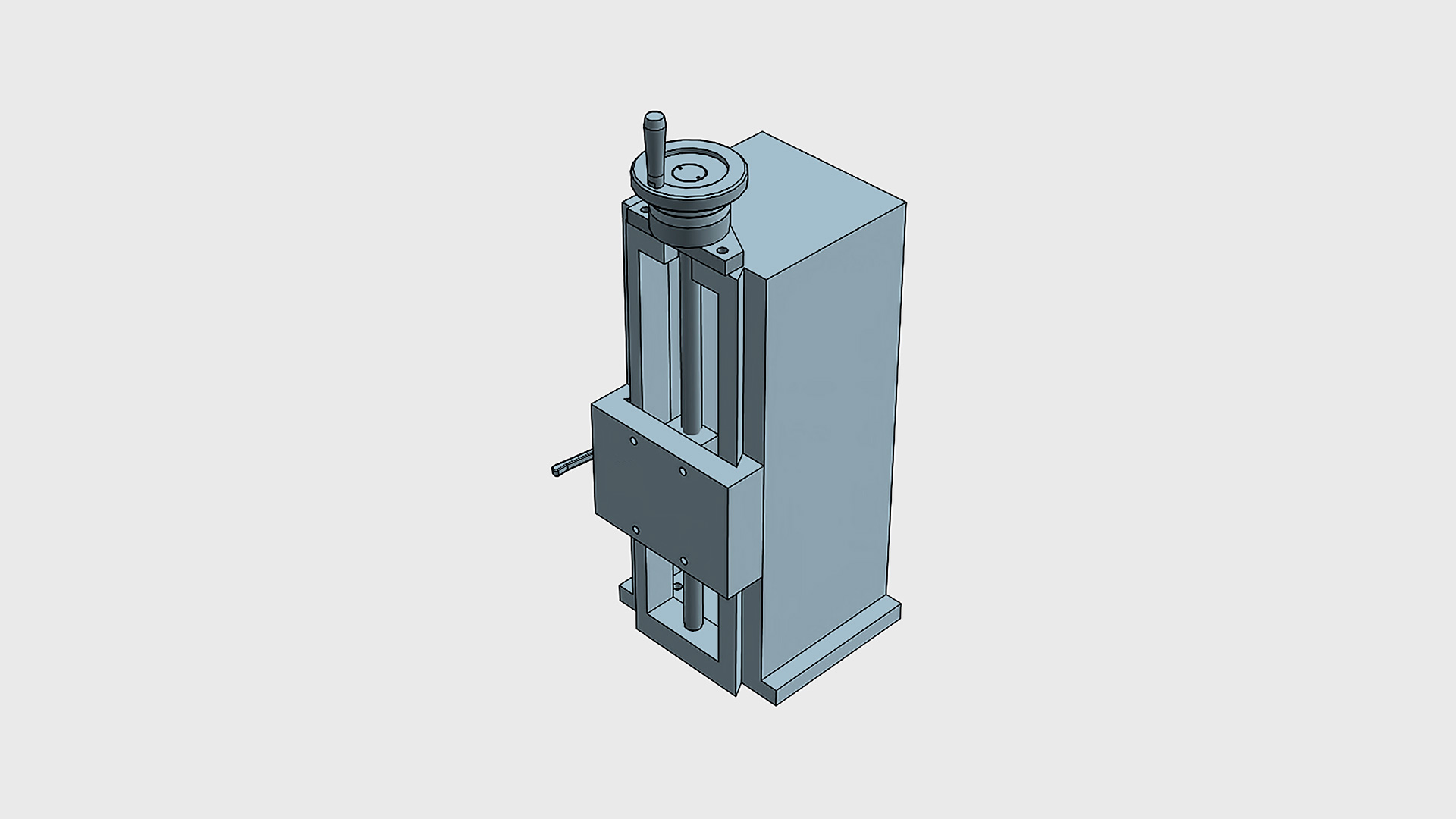

Z Vertical column Z

Vertical coordinate table (Z) for vertical positioning

Designed for precision work, the Z Series of vertical columns is optimal for positioning, vertical drilling, welding, and any other mechanical application where precise Z-position control is required.

The robust and robust design of the linear table allows a large number of jobs to be carried out while maintaining positioning precision and repeatability in any type of linear positioning. An industry classic that guarantees long life.

All Z Series elements are made of cast-iron (high quality GG25 stabilized gray cast iron), giving it extraordinary mechanical rigidity.

Show more

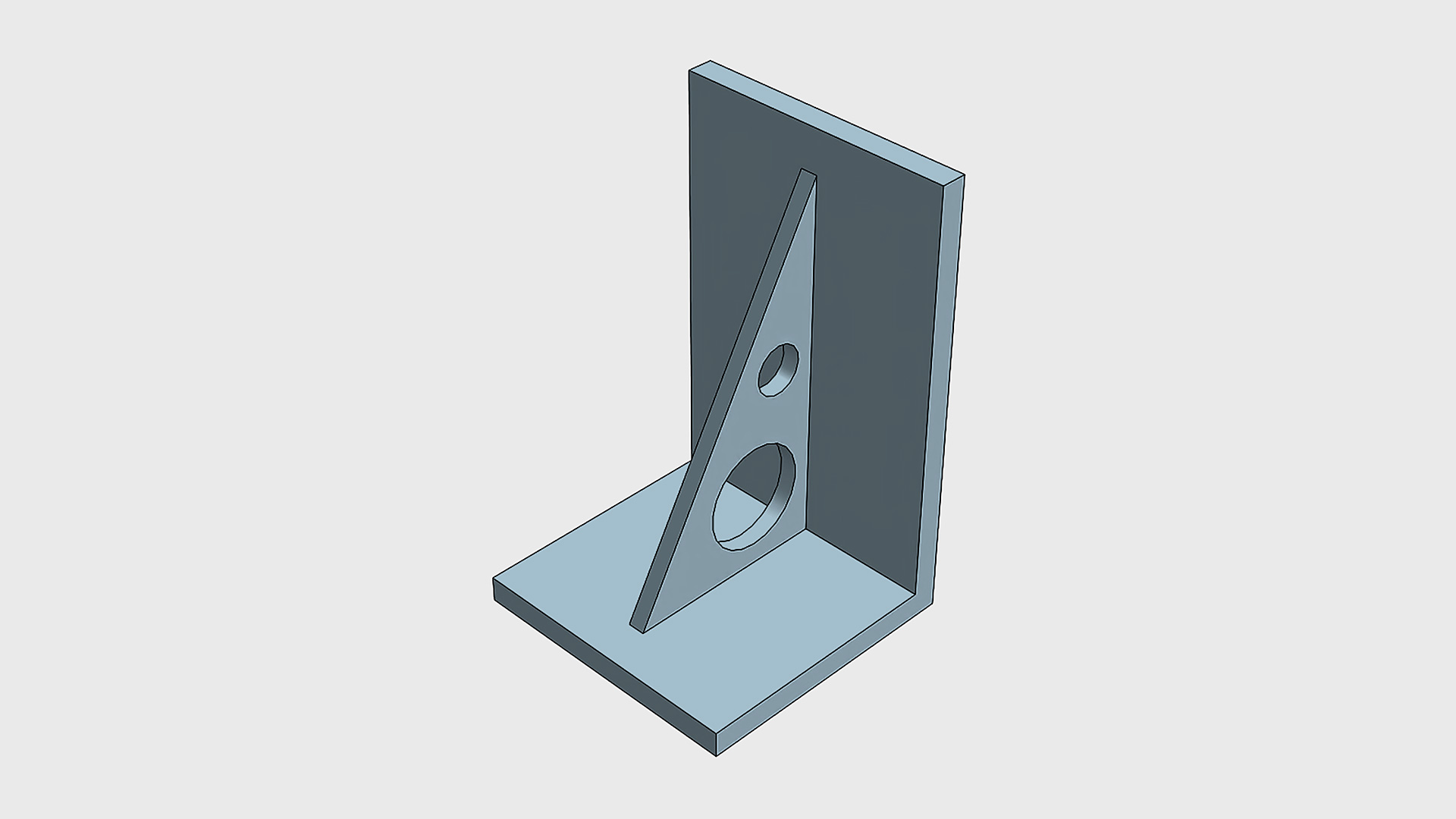

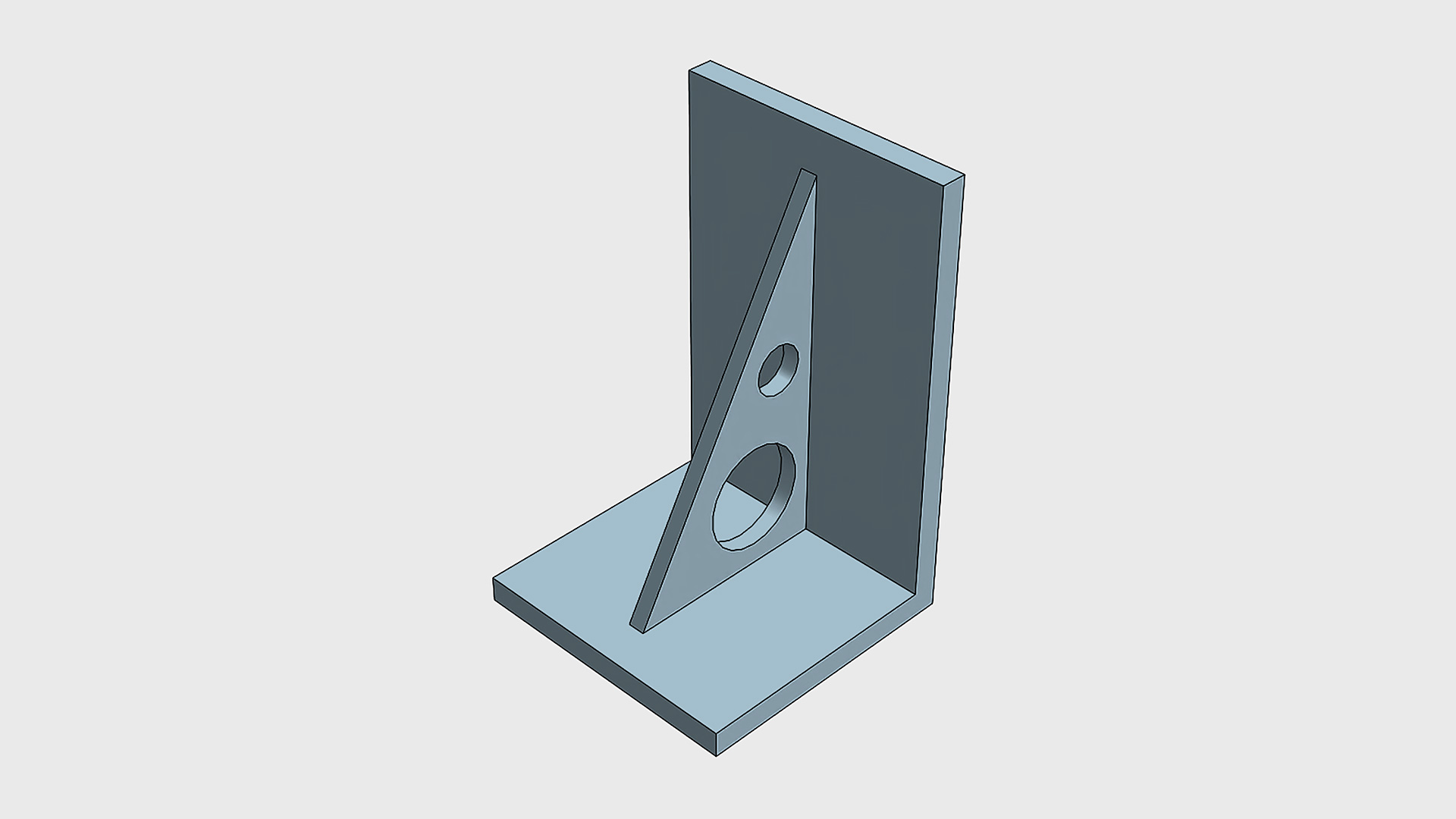

ES Vertical angle plate

Vertical angle plate for special applications and custom assemblies.

The vertical angle plate is used as a complement to our series of coordinate tables for different assemblies and special constructions. The vertical angle plates are supplied without holes so that the user can carry out the applications they want

The robust and robust design of the ES vertical angle plates allows a large number of combined assemblies of BAZUS units.

All the elements of the ES Series are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more