Grinding is a process of machining by abrasion with high accuracy and low roughness than in machining by chip removal. For grinding, robust abrasive discs, called grinding wheels, are used. Grinding is done after the part has undergone other manufacturing processes (milling, turning …). Sometimes a grinding operation is followed by grinding or lapping, such as in the manufacture of lens glasses.

The extraordinary mechanical rigidity of the BAZUS units allow it to absorb the vibrations and stresses generated during grinding, and therefore perform the grinding movement with the repeatability and accuracy necessary to guarantee an optimal result

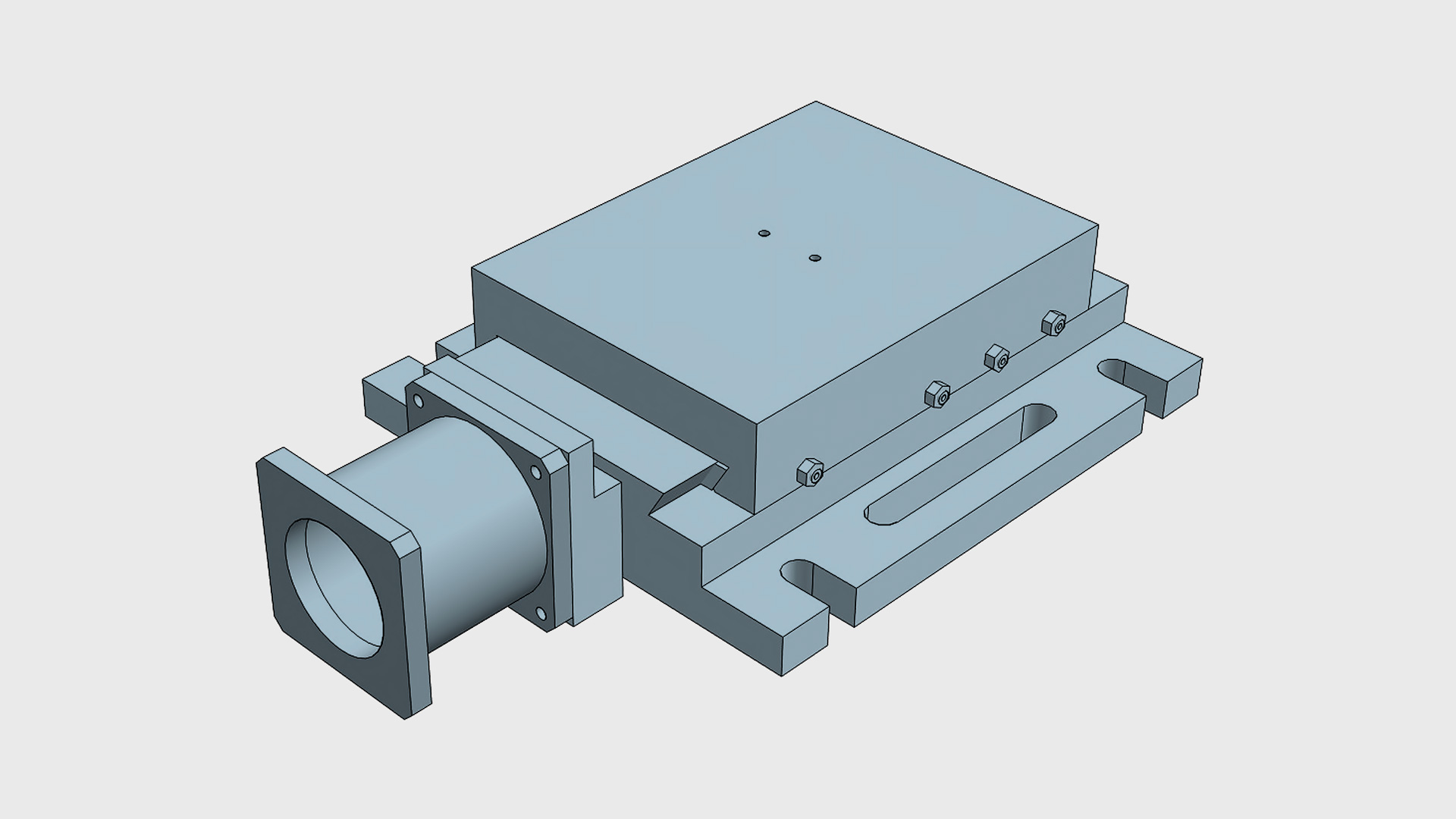

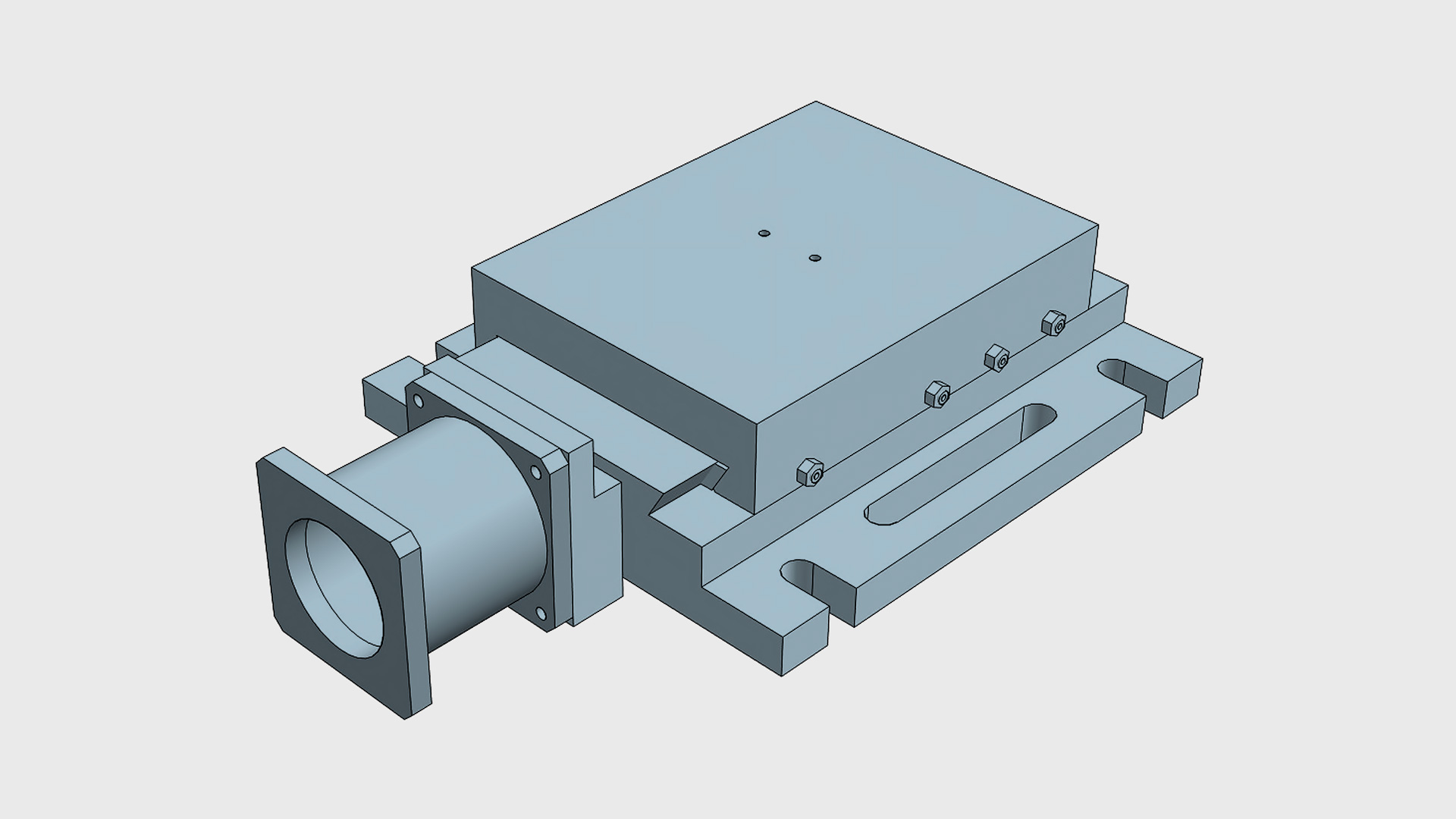

NK Automatic X slide unit (heavy loads)

Robust multifunctional automatic linear unit for professional use with heavy loads

Designed for high precision automatic work, the NK series are optimal linear units for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of tool holder and / or autonomous heads, as well as in any other mechanical application where automatic control of the X position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the PK series automatic coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more

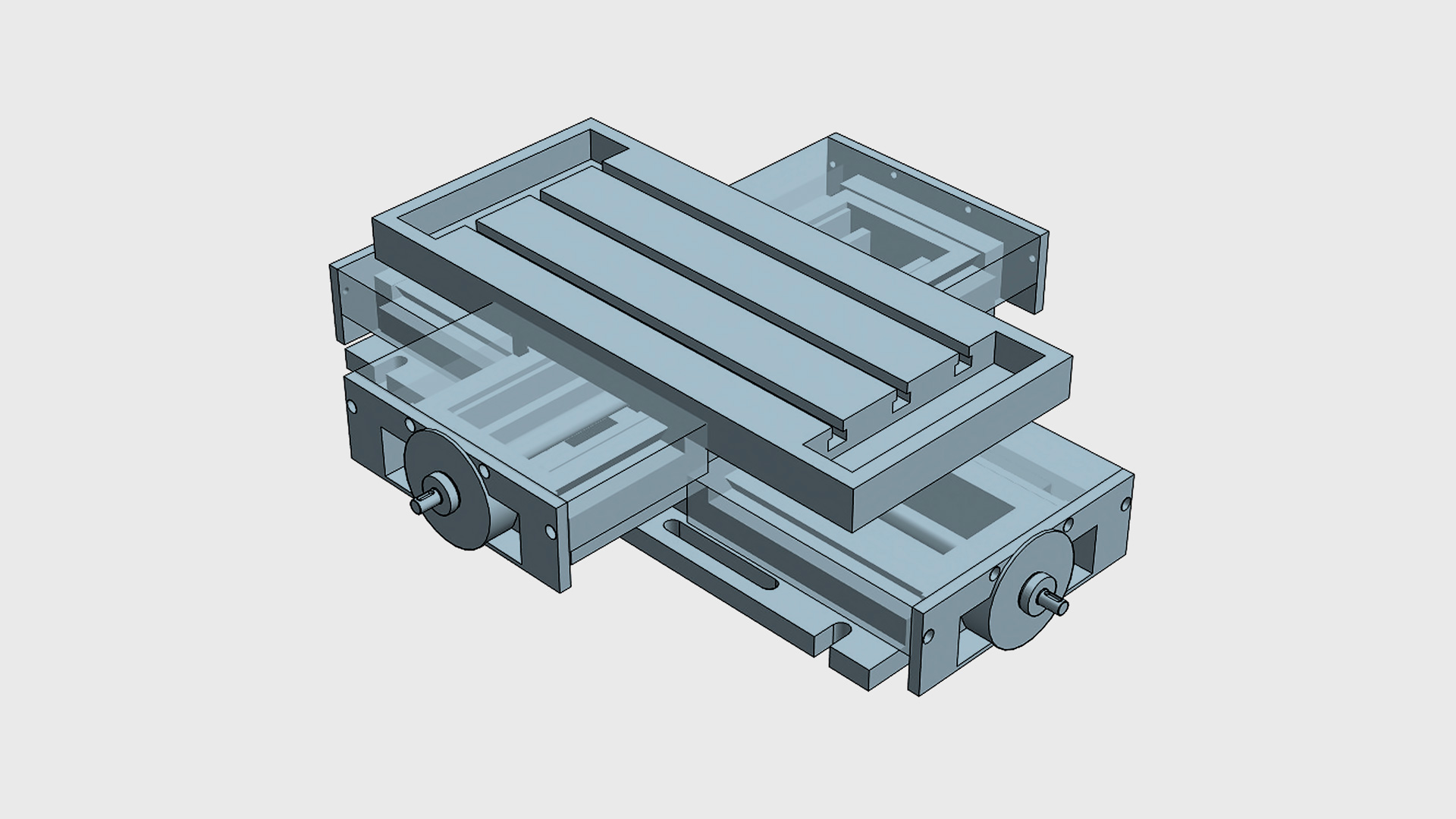

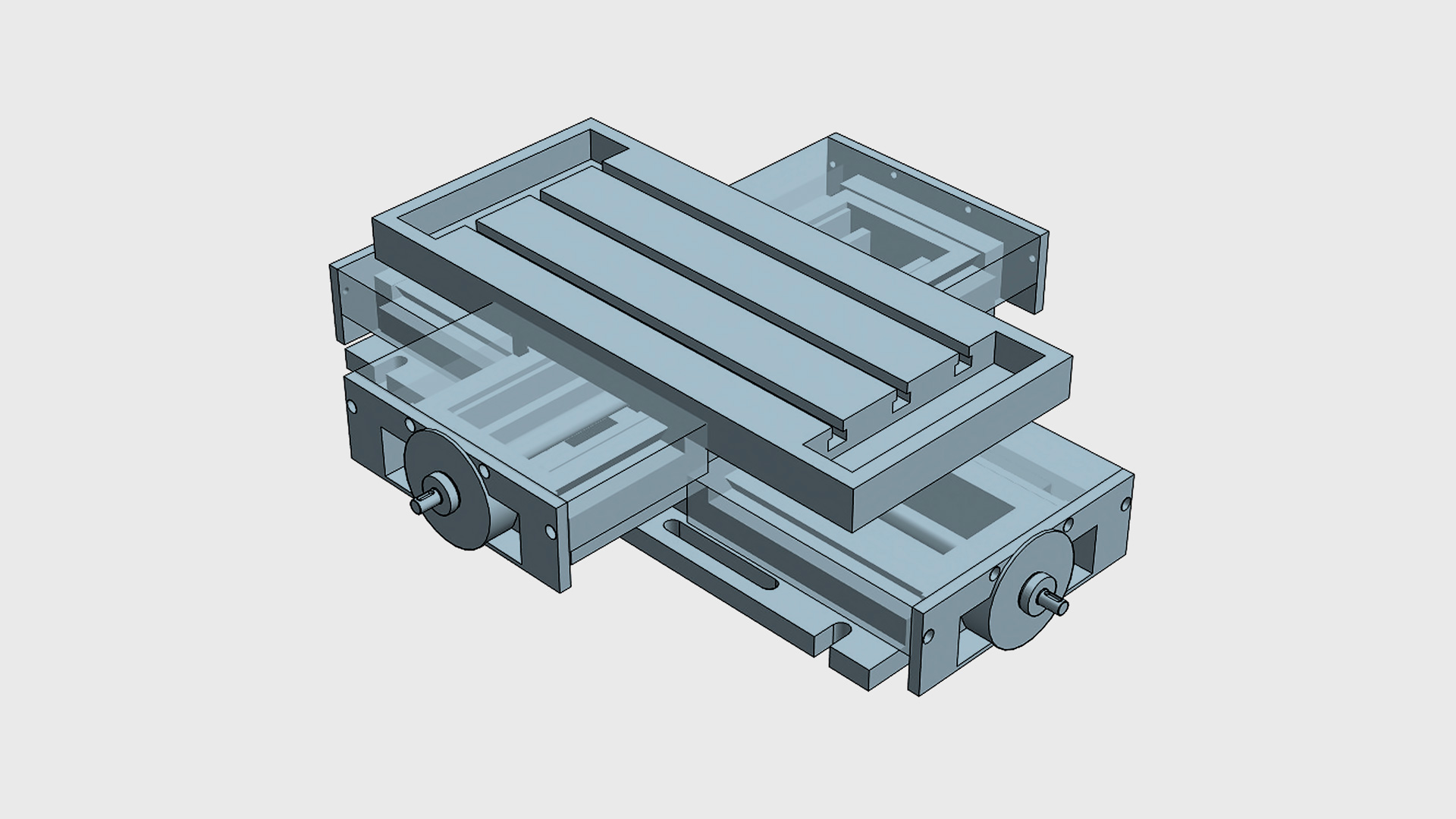

MN Automatic XY crosstables for heavy loads

Coordinate table for heavy loads with two automatic XY axes for professional use

Designed for automatic work with heavy loads, the MN series are optimal coordinate tables for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of autonomous tool holders and / or heads, as well as in any other mechanical application where automatic control of the XY position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the MN series automatic coordinate tables are made of cast iron (high-quality stabilized gray GG25 cast iron), which gives it extraordinary mechanical rigidity.

Show more

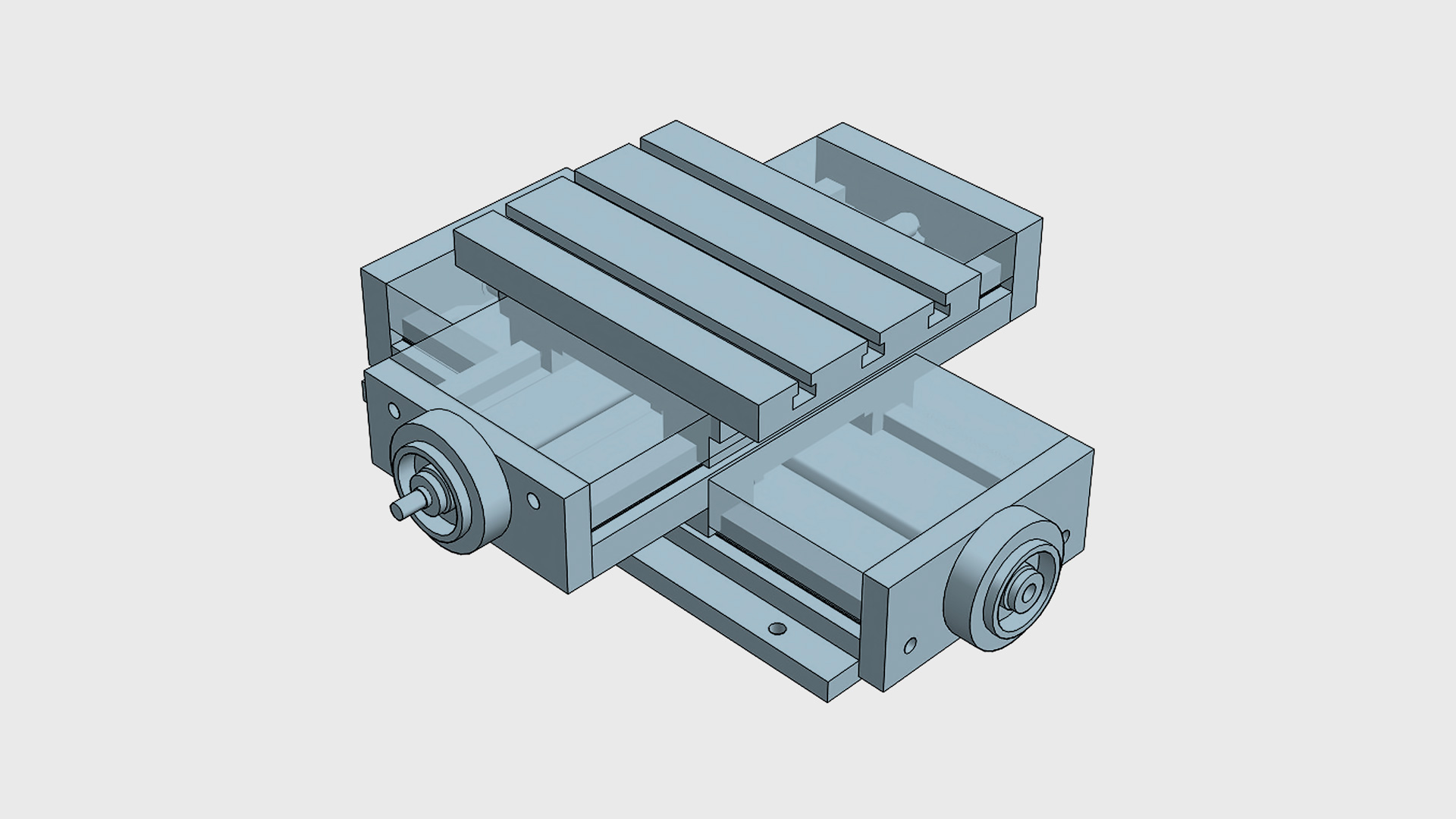

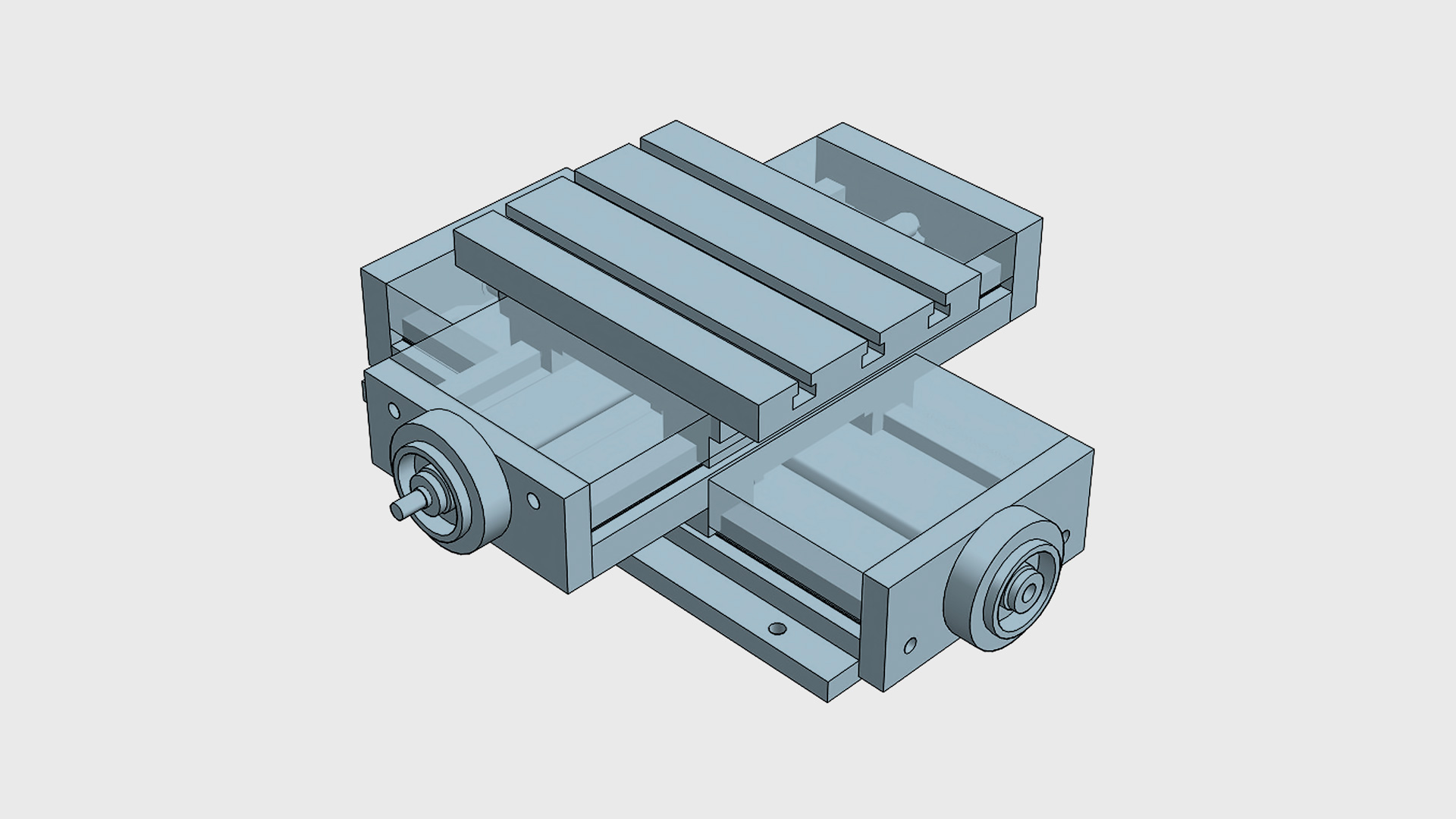

MB Automatic XY crosstables for high-speed

XY automatic two axis high speed coordinate table for professional use

Designed for automatic work with high speed, the MB series are optimal coordinate tables for all types of automatic movement in an industrial environment: drilling, milling, grinding, welding, transfer systems, industrial engraving, automatic positioning of laser and optical systems, movement of autonomous tool holders and / or heads, as well as in any other mechanical application where automatic control of the XY position is necessary.

Its solid and robust design allows a large number of jobs to be carried out while maintaining complete adjustment and positioning accuracy and high repeatability in any type of linear positioning. A coordinate table that excels in the industry for its excellence.

All the elements of the MB series automatic coordinate tables are made of cast iron (high quality GG25 stabilized gray cast iron), which gives it extraordinary mechanical rigidity.

Show more

Kinematik (CNC)

“KINEMATIK SNC”‚ is an automatic positioning system (SNC). It is a simple and, at the same time, an extremely useful solution because it provides the possibility of conducting a large number of activities by programmed movements at specific programmed speeds.

KINEMATIK SNC is controlled by means of the “Quick Panel”, where user find all information to operate with the system in any of its Working Mode (Automatic, Manual and PC Communication). “Quick Panel” is equipped with “Touch screen” to select the Work Mode, buttons Power ON/OFF, Cycle ON /OFF and Emergency Stop.

Show more